Friday, May 6, 2016

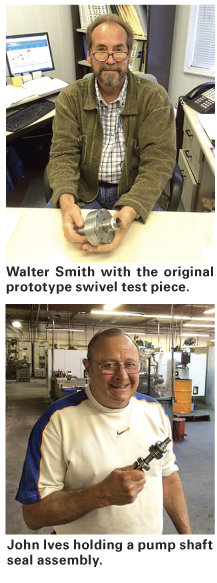

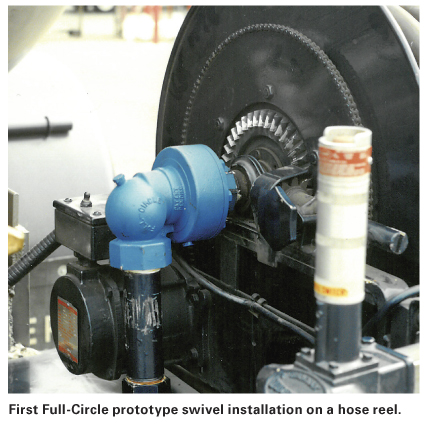

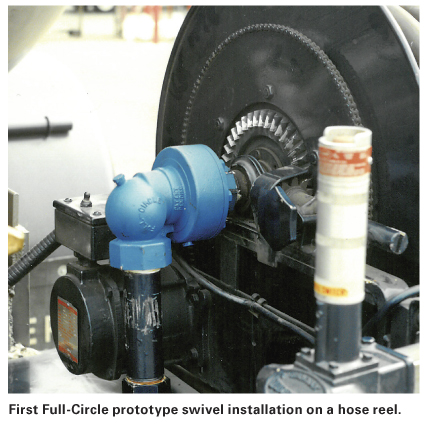

As Full-Circle of Newbury Park, Calif. celebrates its 25th anniversary this year, Walt Smith reflected on how the company started with an off-hand remark. He and sales manager John Ives were setting up a booth at the Western Propane Gas Association convention in 1991 for his company, Smith Precision Products Co., which has been in business since 1938. Bob Bailey, president of Teeco Products but who was then with PACA (Pacific Carburetion Assemblies Inc.), wanted to discuss an idea he had for a swivel at the end of a bobtail delivery hose to connect the hose to the filler valve.  “I wasn’t paying a whole lot of attention. We are pump manufacturers. Our focus and vision is pumps, not swivels,” Smith said. But Smith followed Bailey outside to see how the idea would work with a bobtail. Ives jokingly carried a pump shaft seal assembly with him and gently tossed it to Smith, saying “Here you go, Walt. Here’s a swivel.”

“I wasn’t paying a whole lot of attention. We are pump manufacturers. Our focus and vision is pumps, not swivels,” Smith said. But Smith followed Bailey outside to see how the idea would work with a bobtail. Ives jokingly carried a pump shaft seal assembly with him and gently tossed it to Smith, saying “Here you go, Walt. Here’s a swivel.”

The three of them got a good laugh, but the wheels started spinning in Smith’s head, thinking about how to make the product work.

“I really was not even thinking along the lines of mechanical seals, but in that instance, it was like the heavens opened up: ‘Ah, there it is.’ I don’t think that will ever happen in my lifetime again. It was a very magical, special moment,” Smith recalled. That night, he sketched a design on hotel room stationery. After the show, he and his team developed a crude prototype of the product to see if the concept of using a mechanical seal in a swivel would work.

He called Underwriters Laboratories (UL) to find out if a standard existed for swivels for LP-gas, and he was surprised that such a standard existed, even though no swivels at the time were listed as UL-compliant. He found out why: The endurance test to comply with the standard was challenging. For the test, the swivel is pressurized then rotated back and forth about 100,000 times, but at that time the best swivel submitted by other manufacturers to UL lasted about 30,000 cycles before giving out. He decided to test his prototype.

“When we got up to about 5 million cycles on the prototype without a problem, we knew we had a very special product,” Smith noted. “At that point, I had our guys stop testing, and we took the crude prototype to another level so we could manufacture something that would be acceptable.”

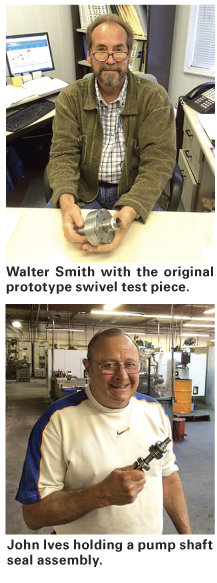

The SMAC-1 was Full-Circle’s first swivel product, and that product led to others. The company investigated another application for the swivel on the hose reel. Full-Circle manufactured its next swivel product for the hose reel, the SMAC 112.

Many people have asked Walt Smith about the product’s numbering system. He explained that the SMAC-1 stands for the 1-in. pipe size. The SMAC-112 stands for 1-1/2-in., and Smith noted that most hose reels on trucks use 1-1/2-in. pipe. But some are 2-in., so the company built the SMAC-200 at the same time.

People also often ask where the name, SMAC, came from. It’s a combination of the words, “Smith” and Bailey’s former company, “PACA.”

As time went on, Full-Circle leaders realized that the industry was using smaller hose reels with 3/4-in. and 1-in. reel hubs. Soon after releasing the SMAC-112, the company began offering smaller hose reel swivels, which are offered in 90º and straight configurations. The 1-in. 90º product is the SMAC 190 and the 3/4-in. is the SMAC-3490. The company went on to offer swivels for low-pressure refined fuels as well, developing a Victaulic coupled design.

Full-Circle then began offering a swivel with two different pipe sizes. One end might be 1-1/2-in., for example, and the other end 2 in. That saves the fabricator having to use an extra fitting,Smith said.

Although the SMAC-1 was a successful product, customers began requesting a smaller size. In response, Full-Circle came out with its current hose-end swivel in 1995: The JO-1, which is about half the size and weight of the original SMAC-1. The JO-1 earned an award from Design News magazine as one of the best-designed products in the country in 1995.

In 1998, the company began offering meter vent flanges.

After working hard for nearly 10 years in the 1990s developing the Full-Circle line, the company was ready to expand its working space again, with Smith noting the business “almost couldn’t fit another machine” into the Newbury Park facility. In 1998, the business purchased its current Yucca Valley, Calif. facility. Smith said that Yucca Valley is purely a production facility, turning raw materials into swivels. Materials are machined, assembled, and tested at that facility, with engineering and order entry still handled at Newbury Park.

As Walt Smith looks to the future, he notes that the fourth generation of the Smith family is working at Smith Precision Products Co. His son, C.J., who started working for the company after graduating from engineering school about four years ago, has carried on the Full-Circle tradition, along with the rest of the team of machinists, assembly/test technicians, and support staff. C.J. designed the company’s stainless steel swivel products.

Overall, Walt Smith is proud of how Full-Circle’s hose-end swivel product line has evolved for the better over the past 25 years. He noted that his company pressure-tests the castings used for hose-reels and other applications before the casting is used to assemble the product. Then the castings are pressure-tested again after assembly.

“We do a lot of little things like that that go above and beyond,” he said. “My mindset early on was this is a new product, we’re forging new territory here, we want to be sure this is the best we can produce. We have managed to live by that philosophy for 25 years. It’s not often a new piece of equipment like one product, the hose-end swivel, is the impetus to start a new company. It’s one reason we’re very grateful the industry has adopted our product and is using it.” —Daryl Lubinsky

The three of them got a good laugh, but the wheels started spinning in Smith’s head, thinking about how to make the product work.

“I really was not even thinking along the lines of mechanical seals, but in that instance, it was like the heavens opened up: ‘Ah, there it is.’ I don’t think that will ever happen in my lifetime again. It was a very magical, special moment,” Smith recalled. That night, he sketched a design on hotel room stationery. After the show, he and his team developed a crude prototype of the product to see if the concept of using a mechanical seal in a swivel would work.

He called Underwriters Laboratories (UL) to find out if a standard existed for swivels for LP-gas, and he was surprised that such a standard existed, even though no swivels at the time were listed as UL-compliant. He found out why: The endurance test to comply with the standard was challenging. For the test, the swivel is pressurized then rotated back and forth about 100,000 times, but at that time the best swivel submitted by other manufacturers to UL lasted about 30,000 cycles before giving out. He decided to test his prototype.

“When we got up to about 5 million cycles on the prototype without a problem, we knew we had a very special product,” Smith noted. “At that point, I had our guys stop testing, and we took the crude prototype to another level so we could manufacture something that would be acceptable.”

The SMAC-1 was Full-Circle’s first swivel product, and that product led to others. The company investigated another application for the swivel on the hose reel. Full-Circle manufactured its next swivel product for the hose reel, the SMAC 112.

Many people have asked Walt Smith about the product’s numbering system. He explained that the SMAC-1 stands for the 1-in. pipe size. The SMAC-112 stands for 1-1/2-in., and Smith noted that most hose reels on trucks use 1-1/2-in. pipe. But some are 2-in., so the company built the SMAC-200 at the same time.

People also often ask where the name, SMAC, came from. It’s a combination of the words, “Smith” and Bailey’s former company, “PACA.”

As time went on, Full-Circle leaders realized that the industry was using smaller hose reels with 3/4-in. and 1-in. reel hubs. Soon after releasing the SMAC-112, the company began offering smaller hose reel swivels, which are offered in 90º and straight configurations. The 1-in. 90º product is the SMAC 190 and the 3/4-in. is the SMAC-3490. The company went on to offer swivels for low-pressure refined fuels as well, developing a Victaulic coupled design.

Full-Circle then began offering a swivel with two different pipe sizes. One end might be 1-1/2-in., for example, and the other end 2 in. That saves the fabricator having to use an extra fitting,Smith said.

Although the SMAC-1 was a successful product, customers began requesting a smaller size. In response, Full-Circle came out with its current hose-end swivel in 1995: The JO-1, which is about half the size and weight of the original SMAC-1. The JO-1 earned an award from Design News magazine as one of the best-designed products in the country in 1995.

In 1998, the company began offering meter vent flanges.

After working hard for nearly 10 years in the 1990s developing the Full-Circle line, the company was ready to expand its working space again, with Smith noting the business “almost couldn’t fit another machine” into the Newbury Park facility. In 1998, the business purchased its current Yucca Valley, Calif. facility. Smith said that Yucca Valley is purely a production facility, turning raw materials into swivels. Materials are machined, assembled, and tested at that facility, with engineering and order entry still handled at Newbury Park.

As Walt Smith looks to the future, he notes that the fourth generation of the Smith family is working at Smith Precision Products Co. His son, C.J., who started working for the company after graduating from engineering school about four years ago, has carried on the Full-Circle tradition, along with the rest of the team of machinists, assembly/test technicians, and support staff. C.J. designed the company’s stainless steel swivel products.

Overall, Walt Smith is proud of how Full-Circle’s hose-end swivel product line has evolved for the better over the past 25 years. He noted that his company pressure-tests the castings used for hose-reels and other applications before the casting is used to assemble the product. Then the castings are pressure-tested again after assembly.

“We do a lot of little things like that that go above and beyond,” he said. “My mindset early on was this is a new product, we’re forging new territory here, we want to be sure this is the best we can produce. We have managed to live by that philosophy for 25 years. It’s not often a new piece of equipment like one product, the hose-end swivel, is the impetus to start a new company. It’s one reason we’re very grateful the industry has adopted our product and is using it.” —Daryl Lubinsky