Friday, May 6, 2016

About five years ago, after Bill Moore began working at Conger LP Gas (Tifton, Ga.), he started programs to grow the company’s agriculture business. Conger LP Gas serves more than 5000 residential, commercial, and agricultural customers. As alternative fuels sales manager, Moore oversees the company’s 150 square miles of sales territory, which covers 28 counties in South Georgia. Initially, he concentrated on marketing autogas and lawn mower conversions, but as the Propane Education & Research Council (PERC) began offering an incentive program to educate the farming community, Moore’s focus expanded as the company pursued a more aggressive strategy in the agricultural segment of its business.

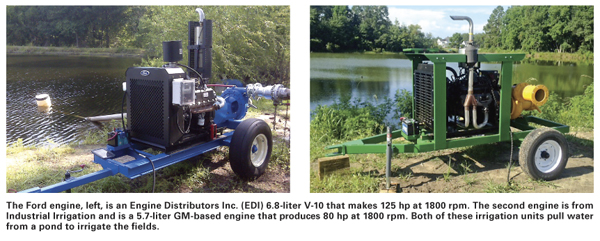

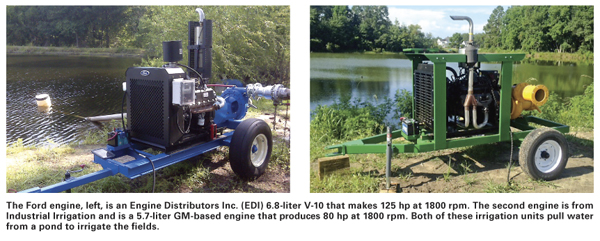

He began talking to farmers about propane-fueled irrigation systems, telling them they can replace their old diesel engines with propane models that are more fuel-efficient and cost-effective.

Past experiences of using propane for many uses on the farm were a big factor that helped Moore’s efforts to educate the ag community. “Propane on the farm has been around a long time,” Moore said. “So in this case it was a reintroduction of a new, more efficient irrigation engine and less costly than diesel, so we’ve just kind of taken that market over the last four years and continued to grow it.”

Moore described his efforts to grow Conger LP Gas’ propane irrigation engine business on April 8 at the National Propane Gas Association (NPGA) Southeastern Convention. Making marketers aware of the various opportunities in the agriculture market was the main goal of Moore’s presentation, said Cinch Munson, PERC’s director of agriculture business development, who also participated in the session. Munson noted the many agricultural opportunities available to propane marketers, including products for grain crops, corn, soybean, tobacco, and cotton, and various applications such as irrigation, grain drying, and poultry house heating and cleaning.

“There are so many different types of agriculture, and so many different types of agriculture equipment, and many of those do, can, and, hopefully, will use propane,” Munson stated.

In addition, Munson discussed how to eliminate the perception among some propane marketers that agriculture is a low-margin business. He acknowledges that its margins are often not as high as they are for residential applications, but he believes that the many uses of propane on the farm add up to a strong opportunity for marketers. For example, a large farm operation might use more than 30,000 gallons of propane for grain drying in a single season.

“A house might not use 30,000 gallons for 100 years. The margins aren’t as large, but the volume is very different. When you start to put all these applications together, you have a farm that’s drying crops, has a vehicle, tractor, lawn mower, building heat, a couple of irrigation engines, and maybe a generator. All of a sudden that volume becomes very big.” Marketers should not automatically think of agriculture negatively, Munson added. If you approach it the right way, it can be a lucrative business.

During the Nashville session, titled, “More Gallons, More Profit, New Opportunities in Agriculture,” Moore told attendees that building relationships with irrigation engine dealers is one of the most important steps in increasing propane irrigation gallon sales. Those dealers are the ones who see the farmers first. In Moore’s Georgia location, the dealers almost always recommend electric irrigation engines because they have historically been the less expensive option. But lower propane prices have provided an important opportunity for propane marketers who want to get into the irrigation engine business.

Moore uses various methods to build relationships with irrigation engine dealers, giving presentations at farmers’ organization meetings and sponsoring some of the events.

“They will give me five minutes to stand up and say, ‘This is what we do.’ And I always carry an irrigation engine with me.” He planned to participate in about 50 events and meet with about 25 farmers over the first three months of this year.

Moore, a PERC advisory committee member who serves on the council’s agriculture project team, notes that about 35 EPA-certified irrigation engines are available through PERC’s incentive programs that offer funding for farmers to purchase propane irrigation systems, and he has access to all of them. When he visits a farmer, he will find out whether the farmer is interested in purchasing a new irrigation system or replacing an old diesel engine.

Moore will find out the horsepower of the farmer’s previous system. “I’ll find a matching engine, and back my way into it. My goal is to swap out his fuel source to something more efficient.”

If the farmer is installing a new irrigation system, Moore will work with the irrigation system dealer to determine how much horsepower is needed for the system. Moore has done all the research and can offer his expertise to show the farmer his best irrigation system options.

In his research, he has also found out that not all propane marketers see the benefits of building the irrigation business due to various reasons. But Moore sees things differently, pointing out that one irrigation engine will use 3000 to 4000 gallons of propane during a heavy irrigation year, a great gallon-grower during the non-peak summer season.

Even smaller propane companies with a large pool of potential farmer customers in their area can build relationships with irrigation dealers and ask to partner with them. By educating the irrigation dealer on the benefits of using propane, marketers will increase the chances of building a new market for propane and increase their gallons and profitability.

When talking to farmers, Moore discusses the cost-effectiveness of propane, and that is especially the case in his area, which limits electricity use during some peak demand periods. For a farmer to get the best rate on electricity, he must go on a peak demand program that cuts off his electricity during peak demand periods. That means the farmer is unable to irrigate his crops during certain periods, but he can run a propane irrigation system whenever he wants.

Portability is another advantage of propane over electricity. With propane irrigation, the farmer can own just one engine and move it from field to field. But if the farmer uses electricity, he must use a separate motor for each area. Instead of spending $15,000 per field, or $45,000 for three electric pumps, plus connection costs at each location, the farmer can spend $15,000 for one propane engine.

Other advantages are region-specific. California emissions standards are more stringent than in other areas of the country, so a propane marketer in that state could sell the clean-burning advantages of propane to a farmer. At the end of the day, however, farmers don’t care as much about how clean-burning the fuel is than about how it can save them money. —Daryl Lubinsky

He began talking to farmers about propane-fueled irrigation systems, telling them they can replace their old diesel engines with propane models that are more fuel-efficient and cost-effective.

Past experiences of using propane for many uses on the farm were a big factor that helped Moore’s efforts to educate the ag community. “Propane on the farm has been around a long time,” Moore said. “So in this case it was a reintroduction of a new, more efficient irrigation engine and less costly than diesel, so we’ve just kind of taken that market over the last four years and continued to grow it.”

Moore described his efforts to grow Conger LP Gas’ propane irrigation engine business on April 8 at the National Propane Gas Association (NPGA) Southeastern Convention. Making marketers aware of the various opportunities in the agriculture market was the main goal of Moore’s presentation, said Cinch Munson, PERC’s director of agriculture business development, who also participated in the session. Munson noted the many agricultural opportunities available to propane marketers, including products for grain crops, corn, soybean, tobacco, and cotton, and various applications such as irrigation, grain drying, and poultry house heating and cleaning.

“There are so many different types of agriculture, and so many different types of agriculture equipment, and many of those do, can, and, hopefully, will use propane,” Munson stated.

In addition, Munson discussed how to eliminate the perception among some propane marketers that agriculture is a low-margin business. He acknowledges that its margins are often not as high as they are for residential applications, but he believes that the many uses of propane on the farm add up to a strong opportunity for marketers. For example, a large farm operation might use more than 30,000 gallons of propane for grain drying in a single season.

“A house might not use 30,000 gallons for 100 years. The margins aren’t as large, but the volume is very different. When you start to put all these applications together, you have a farm that’s drying crops, has a vehicle, tractor, lawn mower, building heat, a couple of irrigation engines, and maybe a generator. All of a sudden that volume becomes very big.” Marketers should not automatically think of agriculture negatively, Munson added. If you approach it the right way, it can be a lucrative business.

During the Nashville session, titled, “More Gallons, More Profit, New Opportunities in Agriculture,” Moore told attendees that building relationships with irrigation engine dealers is one of the most important steps in increasing propane irrigation gallon sales. Those dealers are the ones who see the farmers first. In Moore’s Georgia location, the dealers almost always recommend electric irrigation engines because they have historically been the less expensive option. But lower propane prices have provided an important opportunity for propane marketers who want to get into the irrigation engine business.

Moore uses various methods to build relationships with irrigation engine dealers, giving presentations at farmers’ organization meetings and sponsoring some of the events.

“They will give me five minutes to stand up and say, ‘This is what we do.’ And I always carry an irrigation engine with me.” He planned to participate in about 50 events and meet with about 25 farmers over the first three months of this year.

Moore, a PERC advisory committee member who serves on the council’s agriculture project team, notes that about 35 EPA-certified irrigation engines are available through PERC’s incentive programs that offer funding for farmers to purchase propane irrigation systems, and he has access to all of them. When he visits a farmer, he will find out whether the farmer is interested in purchasing a new irrigation system or replacing an old diesel engine.

Moore will find out the horsepower of the farmer’s previous system. “I’ll find a matching engine, and back my way into it. My goal is to swap out his fuel source to something more efficient.”

If the farmer is installing a new irrigation system, Moore will work with the irrigation system dealer to determine how much horsepower is needed for the system. Moore has done all the research and can offer his expertise to show the farmer his best irrigation system options.

In his research, he has also found out that not all propane marketers see the benefits of building the irrigation business due to various reasons. But Moore sees things differently, pointing out that one irrigation engine will use 3000 to 4000 gallons of propane during a heavy irrigation year, a great gallon-grower during the non-peak summer season.

Even smaller propane companies with a large pool of potential farmer customers in their area can build relationships with irrigation dealers and ask to partner with them. By educating the irrigation dealer on the benefits of using propane, marketers will increase the chances of building a new market for propane and increase their gallons and profitability.

When talking to farmers, Moore discusses the cost-effectiveness of propane, and that is especially the case in his area, which limits electricity use during some peak demand periods. For a farmer to get the best rate on electricity, he must go on a peak demand program that cuts off his electricity during peak demand periods. That means the farmer is unable to irrigate his crops during certain periods, but he can run a propane irrigation system whenever he wants.

Portability is another advantage of propane over electricity. With propane irrigation, the farmer can own just one engine and move it from field to field. But if the farmer uses electricity, he must use a separate motor for each area. Instead of spending $15,000 per field, or $45,000 for three electric pumps, plus connection costs at each location, the farmer can spend $15,000 for one propane engine.

Other advantages are region-specific. California emissions standards are more stringent than in other areas of the country, so a propane marketer in that state could sell the clean-burning advantages of propane to a farmer. At the end of the day, however, farmers don’t care as much about how clean-burning the fuel is than about how it can save them money. —Daryl Lubinsky