Thursday, May 12, 2016

The U.S. Virgin Islands’ conversion to LPG for electrical power generation is hailed as a first of what is hoped will be many such projects, and further, a model for other island power authorities and small utilities serving confined areas to emulate. Lessons learned from the territory’s ambitious initiative can be adopted so more can enjoy the benefits of a cleaner, less expensive fuel that benefits the utility and ratepayers while at the same time improves air quality and treads more lightly on the environment. “This project is the first of many more,” declares Hugo V. Hodge Jr., past executive director of the Virgin Islands Water and Power Authority (WAPA). “The economics are there. This project is a living, breathing example for others to view.”

Less expensive, cleaner propane is changing how countries, territories, and insular areas view propane. A presentation by Hodge at the 2016 Argus Americas LPG Summit outlined WAPA’s enterprising retrofit of power generators on Saint Thomas and Saint Croix to run on propane, an approved, clean alternative fuel listed in the 1990 Clean Air Act and the Energy Policy Act of 1992. Hodge, currently co-director of the Energy Development in Island Nations-U.S. Virgin Islands initiative, a collaborative federal and local effort to reduce fossil fuel usage in the islands by 60% by 2025, oversaw the conversion project from its start through the permitting process and construction during his eight-year tenure as head of WAPA. The conversion was designed so generators are principally fueled by LPG, but can switch to other sources such as fueloil or natural gas on the fly.

WAPA, a government-owned utility, is the primary source of water and power production and distribution in the U.S. territory. Prior to the conversion, electrical power was generated 92% by No. 2 fueloil and 8% by solar. The territorial peak power rating on Saint Thomas/Saint John is 58 megawatts (MW) per minute — 65 MW maximum on a seasonal average. Saint Croix is 33 MW/min.— 39 MW maximum. Historical rates are 88 MW and 55 MW, respectively. In fiscal year 2015, WAPA operating expense was $330,710,000, of which $231,479,000 was fuel cost, 70% of 2014 operating expense. “Typical fuel cost is 16 cents per kilowatt hour; customer cost is 29 to 32 cents per kilowatt hour. Rates ran as high as 55 cents per kilowatt hour at the peak of oil prices,” Hodge said. “This is the highest cost for electricity compared with any other U.S. state, territory, or possession.”

Compounding matters, in 2012 the islands’ 350,000-bbld Hovensa refinery was shuttered by owners Hess Corp. and Venezuelan state-owned Petróleos de Venezuela SA. Losses over three years of $1.3 billion persuaded them to shut down the facility, resulting in more than 2200 full-time and contract workers losing their jobs and lucrative tax revenues to the local government drying up. Although Hovensa was a major supplier to the U.S. with the ability to source low-sulfur crude from Africa and some higher-sulfur crude from Venezuela, it lost money. Specifically, with its sudden closure, advantaged fuel contracts WAPA enjoyed were severed and the utility had to scramble for alternative sources for fuel, further burdening the utility’s bottom line and ratepayers’ wallets.

Industry analysts noted that the refinery’s death knell was its fuel source. U.S. refiners use cheap, plentiful natural gas for power while Hovensa, surrounded on all sides by water, had to use the fueloil it produced for power. “Hovensa had the same basic problem the Virgin Islands public utility does, it uses an expensive fuel to make electricity, which costs more than electricity might cost if generated by using a lower-cost fuel,” noted former U.S. Virgin Islands Gov. John P. de Jongh.

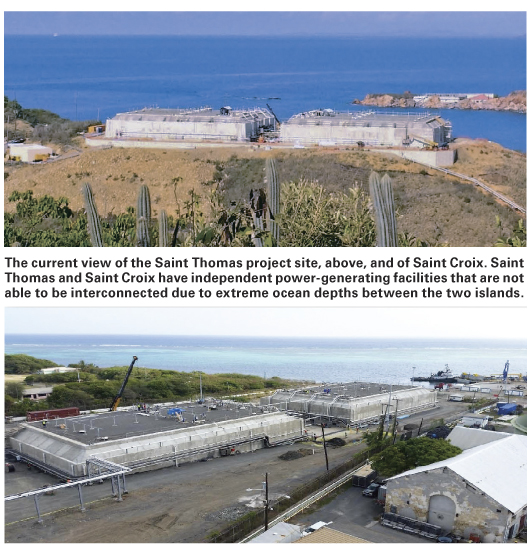

“Closure of the Hovensa refinery resulted in the loss of approximately $50 million in fueloil savings from incentive pricing, resulting in a significant adverse impact on the territory’s residents and economy,” Hodge said. He explained that Saint Thomas and Saint Croix have independent power generating facilities that are not able to be interconnected due to the extreme ocean depths between the two islands. WAPA needed to respond, and quickly. “In September 2012 WAPA issued a request for quotes for the islands’ fuel conversion project — LNG and LPG — with a preference for a turnkey solution including fuel supply and infrastructure,” the certified power quality professional said. “In November 2012, three finalists were invited to submit proposals for an LPG solution, and in April 2013 WAPA reviewed final proposals.”

Hodge commented that the utility looked initially at LNG, but the deep draft of the delivery vessels and logistics and fuel sourcing proved problematic. Ultimately, LPG was chosen to provide a solution. In July 2013 Vitol was selected as the project partner for infrastructure upgrades and propane supply. The Geneva-based energy and commodities company has physical trading, logistics, and distribution at the core of its worldwide business, complemented by refining, shipping, terminals, exploration and production, power generation, mining, and retail operations.

“Vitol invests in a number of ventures, providing terminal and storage facilities globally,” Hodge noted. “The company’s key statistics for 2014 include $270 billion in revenues, 268 million tonnes of crude oil and products shipped, more than five million barrels of crude and other products traded every day, and 6053 ship voyages. Vitol has 200 ships at sea at any one time. Very impressive.”

WAPA entered into a master agreement with Vitol for infrastructure construction, conversion of seven existing combustion General Electric turbines, and supply of propane. The contract required plans to receive, store, vaporize, measure, and deliver propane to power plants on the islands of Saint Thomas and Saint Croix. “Vitol was responsible for engineering, procurement, construction, and commission of the project, whose cost was approximately $150 million,” Hodge said. “All upfront costs were paid by Vitol. WAPA will repay Vitol over a 10-year amortization built into the fuel costs, with an option to repay in seven years.” The utility expects to realize a reduction in its fuel costs of 30% or more, as well as reducing greenhouse gas emissions by 20%.

Hodge characterized the conversion as a first-class project that incorporated safety measures encompassing monitoring and detection with state-of-the-art technologies. Best industry practices were enforced to ensure environmental benefits such as nitrogen oxide, sulfur oxide, and carbon dioxide emissions reductions. “Economic benefits were realized through fuel cost savings derived from low propane prices compared to fueloil, and savings in working capital for WAPA as fuel inventory is carried by Vitol,” Hodge outlined. “Vitol has committed $140 million to date.”

In testimony before the U.S. Senate Committee on Energy and Natural Resources last year, Hodge commented on remote and isolated energy systems, including energy and infrastructure challenges and opportunities. He provided an overview of WAPA’s challenges, including being significantly dependent on fueloil for generating electricity. “While the territory has received some relief recently due to the decline in oil prices, which has reduced the electric rate to 32 cents per kilowatt hour for residential customers and 35 cents per kilowatt hour for commercial customers, analysts are divided on how long this respite from high fuel prices will last. One thing is certain, however, prices will elevate again, and so the urgency remains the same.”

Hodge was among representatives of Guam, Alaska, and Hawaii outlining the challenges remote island electric system operators face in generating electricity. He noted that, like most other islands in the Caribbean, the Virgin Islands has no conventional energy resources to meet its energy needs. “While U.S. mainland utilities can connect to grids to purchase power from other utilities, island utilities are small, isolated, and are not interconnected to a grid comprised of other utilities. This is primarily due to their separation by water and the depth of the ocean floor, which makes interconnection via underwater electric cables technically and economically unfeasible. As a result, island utilities have historically purchased small, simple-cycle generating units that are oil-fueled.”

Hodge told the committee that since fuel prices began to skyrocket more than 10 years ago, WAPA pursued every option to reduce the cost of electric services to the people of the Virgin Islands. “We have pursued alternative and renewable sources tirelessly for almost 10 years now, and tangible relief is finally on the horizon.” WAPA could not, however, have made the advances that it has without a number of strategic public and private partnerships.

He testified that WAPA’s primary supporters have been the executive and legislative branches of the Virgin Islands government, and on the federal level, the Department of the Interior, the Department of Energy’s National Renewable Energy Laboratory, the Federal Emergency Management Agency, and the Department of Agriculture’s Rural Utilities Service. The National Renewable Energy Laboratory helped identify the territory’s baseline energy use and laid out how the Virgin Islands could best meet its goal of achieving a 60% reduction in the use of fossil fuel by 2025. The Interior Department provided a $500,000 grant to prepare an integrated resource plan that provided a roadmap for determining future generation needs. The Federal Emergency Management Agency funded hazard mitigation projects that assisted with burying power lines that serve critical areas of the territory. The Rural Utilities Service approved a loan that allowed WAPA to implement distribution automation technology, including the development of a smart electric grid and advanced metering infrastructure and automated meter reading. Hodge reviewed that, until October 2014, WAPA was 100% dependent on fueloil to produce power. Since that time, the utility has placed on its grid about 8.2 megawatts of solar power.

The Virgin Islands propane conversion project involved more than 200,768 man hours expended on both Saint Thomas and Saint Croix, with about 130,000 hours of local U.S. Virgin Islands man hours, he said. Vitol contracted directly or indirectly with numerous local contractors. Construction took place over 18 months after front-end engineering and design was completed and construction permits were issued.

Storage tanks, manufactured by Geldof Integrated Steel Solutions of Belgium, are mounded, encased by layers of earth, sand, rock, and gravel to maximize safety. Benefits of the installation include providing a significant protective barrier from external damage and fire; elimination of oxygen, preventing uncontrolled ignition; and additional earthquake and hurricane protection. Capacity is 10,400 cubic meters in eight tanks on Saint Croix, which provides 19.2 days of effective supply, while on Saint Thomas there are 14,000 cubic meters in 10 tanks with an 18.3-day supply.

“Facilities were carefully designed to ensure employees’ and the public’s health, safety, and protection,” Hodge emphasized. “There are emergency response plans for each facility and all existing applicable environmental permits and plans are being updated. Fire safety features are designed for 100% redundancy, and firefighting systems are National Fire Protection Association-compliant and include a water blanket to suppress a leak or flame. Facilities are equipped with gas monitoring and leak-detection systems.”

As with any major project, there were challenges. “Throughout the propane conversion process, complications and unforeseen circumstances impacted project progress and the completion schedule — adverse weather conditions, undocumented soil conditions and underground obstacles, and the volume of rock needed to be removed was much greater than anticipated,” said Hodge. He added that there were greater challenges than expected in coordinating the power plant conversions while simultaneously operating the facilities to meet daily electricity demand.

Other circumstances that contributed to project schedule adjustments included extended work that was required for the design, procurement, and installation of the resources to upgrade existing fire protection, controls, and other systems for the safe use of propane, and complexity in permitting, contracting, demolishing, and disposing of structures with lead-based paint. “Then there was the reality of global sourcing of all the materials and equipment for the project,” Hodge elaborated. “And there were additional regulatory requirements to further assure compliance with safety and security of the project’s marine scope, which included new engineering and redesigns.”

WAPA received its first inventory of propane in October 2015 at the Richmond terminal. The fuel was used for commissioning and testing of the storage and delivery systems ahead of the utility’s generating units burning propane to produce electricity. In January of this year WAPA received the long-awaited permit from the U.S. Army Corps of Engineers that allowed it to proceed with work on the marine side of the LPG project at the Randolph Harley Power Plant, and to develop an offshore vessel mooring off Saint Thomas. The permit allowed WAPA to improve, enhance, and convert the existing fuel pier at the Harley plant and the offshore mooring.

All components of the marine work had been dependent on the permit’s approval. WAPA applied for the permit in December 2013. The very large gas carrier (VLGC) permanent mooring site was tied to the permit for Saint Thomas. Prior to its receipt, and so not to delay propane deliveries to Saint Croix, the authority identified a temporary anchoring site for both the feeder-fuel vessels and the VLGC offshore of Aruba.

Other milestones for the project include the completion of mechanical terminal facilities in November 2015, an upgrade of fire suppression systems in January 2016, and the commissioning of propane turbines in February 2016. Major land and water permits for both island projects have been approved, and initial storm water permits for construction activities for both terminals have been issued. An operating storm water permit will be issued after construction is completed. Emergency response plans have been modified and updated to reflect the use of LPG, and a waterway suitability assessment plan, focusing on waterside safety and security, has been approved by the U.S. Coast Guard.

The Virgin Islands Territorial Emergency Management Agency and the U.S. Department of Homeland Security are finalizing an independent vulnerability assessment study to ensure compliance with local and federal mandates for safety and security. “All precautions were taken to protect the wellbeing of the general public, employees, and first responders,” Hodge said. “Partnerships have been structured to expand communication on public awareness, safety, and the security measures of the project.”

Employees are being fully trained on the operation and maintenance of the converted power generation units, including all safety and hazard awareness required for the handling and use of propane. There is also extensive coordination with local fire services and other first responders. Advanced safety and security drills have been conducted with WAPA and local emergency response organizations.

Two new propane delivery vessels, the Epic Curacao and Epic Caledonia, have been built and commissioned to deliver propane to WAPA’s facilities, Hodge said. Crews have conducted advance navigation simulations with Virgin Islands Port Authority harbor pilots to ensure the safe transit of vessels into and out of WAPA docking facilities.

In early April WAPA’s project achieved another milestone when the Unit 20 generating unit on Saint Croix was commissioned for LPG. On Saint Thomas, marine work, including the installation of fenders and other dock improvements to accommodate propane vessels, was proceeding. Work on the land side involved the installation of a marine loading arm. It is anticipated that a similar commissioning of generating units on Saint Thomas would begin in August.

“The LPG project represents the best near-term option for the U.S. Virgin Islands to significantly reduce the cost of fuel for power generation while ensuring widespread benefits for the territory,” Hodge observed. “Propane will provide affordable power and water and lower the cost of living, spur economic growth, enable new business startups, and lower emissions.” —John Needham

Less expensive, cleaner propane is changing how countries, territories, and insular areas view propane. A presentation by Hodge at the 2016 Argus Americas LPG Summit outlined WAPA’s enterprising retrofit of power generators on Saint Thomas and Saint Croix to run on propane, an approved, clean alternative fuel listed in the 1990 Clean Air Act and the Energy Policy Act of 1992. Hodge, currently co-director of the Energy Development in Island Nations-U.S. Virgin Islands initiative, a collaborative federal and local effort to reduce fossil fuel usage in the islands by 60% by 2025, oversaw the conversion project from its start through the permitting process and construction during his eight-year tenure as head of WAPA. The conversion was designed so generators are principally fueled by LPG, but can switch to other sources such as fueloil or natural gas on the fly.

WAPA, a government-owned utility, is the primary source of water and power production and distribution in the U.S. territory. Prior to the conversion, electrical power was generated 92% by No. 2 fueloil and 8% by solar. The territorial peak power rating on Saint Thomas/Saint John is 58 megawatts (MW) per minute — 65 MW maximum on a seasonal average. Saint Croix is 33 MW/min.— 39 MW maximum. Historical rates are 88 MW and 55 MW, respectively. In fiscal year 2015, WAPA operating expense was $330,710,000, of which $231,479,000 was fuel cost, 70% of 2014 operating expense. “Typical fuel cost is 16 cents per kilowatt hour; customer cost is 29 to 32 cents per kilowatt hour. Rates ran as high as 55 cents per kilowatt hour at the peak of oil prices,” Hodge said. “This is the highest cost for electricity compared with any other U.S. state, territory, or possession.”

Compounding matters, in 2012 the islands’ 350,000-bbld Hovensa refinery was shuttered by owners Hess Corp. and Venezuelan state-owned Petróleos de Venezuela SA. Losses over three years of $1.3 billion persuaded them to shut down the facility, resulting in more than 2200 full-time and contract workers losing their jobs and lucrative tax revenues to the local government drying up. Although Hovensa was a major supplier to the U.S. with the ability to source low-sulfur crude from Africa and some higher-sulfur crude from Venezuela, it lost money. Specifically, with its sudden closure, advantaged fuel contracts WAPA enjoyed were severed and the utility had to scramble for alternative sources for fuel, further burdening the utility’s bottom line and ratepayers’ wallets.

Industry analysts noted that the refinery’s death knell was its fuel source. U.S. refiners use cheap, plentiful natural gas for power while Hovensa, surrounded on all sides by water, had to use the fueloil it produced for power. “Hovensa had the same basic problem the Virgin Islands public utility does, it uses an expensive fuel to make electricity, which costs more than electricity might cost if generated by using a lower-cost fuel,” noted former U.S. Virgin Islands Gov. John P. de Jongh.

“Closure of the Hovensa refinery resulted in the loss of approximately $50 million in fueloil savings from incentive pricing, resulting in a significant adverse impact on the territory’s residents and economy,” Hodge said. He explained that Saint Thomas and Saint Croix have independent power generating facilities that are not able to be interconnected due to the extreme ocean depths between the two islands. WAPA needed to respond, and quickly. “In September 2012 WAPA issued a request for quotes for the islands’ fuel conversion project — LNG and LPG — with a preference for a turnkey solution including fuel supply and infrastructure,” the certified power quality professional said. “In November 2012, three finalists were invited to submit proposals for an LPG solution, and in April 2013 WAPA reviewed final proposals.”

Hodge commented that the utility looked initially at LNG, but the deep draft of the delivery vessels and logistics and fuel sourcing proved problematic. Ultimately, LPG was chosen to provide a solution. In July 2013 Vitol was selected as the project partner for infrastructure upgrades and propane supply. The Geneva-based energy and commodities company has physical trading, logistics, and distribution at the core of its worldwide business, complemented by refining, shipping, terminals, exploration and production, power generation, mining, and retail operations.

“Vitol invests in a number of ventures, providing terminal and storage facilities globally,” Hodge noted. “The company’s key statistics for 2014 include $270 billion in revenues, 268 million tonnes of crude oil and products shipped, more than five million barrels of crude and other products traded every day, and 6053 ship voyages. Vitol has 200 ships at sea at any one time. Very impressive.”

WAPA entered into a master agreement with Vitol for infrastructure construction, conversion of seven existing combustion General Electric turbines, and supply of propane. The contract required plans to receive, store, vaporize, measure, and deliver propane to power plants on the islands of Saint Thomas and Saint Croix. “Vitol was responsible for engineering, procurement, construction, and commission of the project, whose cost was approximately $150 million,” Hodge said. “All upfront costs were paid by Vitol. WAPA will repay Vitol over a 10-year amortization built into the fuel costs, with an option to repay in seven years.” The utility expects to realize a reduction in its fuel costs of 30% or more, as well as reducing greenhouse gas emissions by 20%.

Hodge characterized the conversion as a first-class project that incorporated safety measures encompassing monitoring and detection with state-of-the-art technologies. Best industry practices were enforced to ensure environmental benefits such as nitrogen oxide, sulfur oxide, and carbon dioxide emissions reductions. “Economic benefits were realized through fuel cost savings derived from low propane prices compared to fueloil, and savings in working capital for WAPA as fuel inventory is carried by Vitol,” Hodge outlined. “Vitol has committed $140 million to date.”

In testimony before the U.S. Senate Committee on Energy and Natural Resources last year, Hodge commented on remote and isolated energy systems, including energy and infrastructure challenges and opportunities. He provided an overview of WAPA’s challenges, including being significantly dependent on fueloil for generating electricity. “While the territory has received some relief recently due to the decline in oil prices, which has reduced the electric rate to 32 cents per kilowatt hour for residential customers and 35 cents per kilowatt hour for commercial customers, analysts are divided on how long this respite from high fuel prices will last. One thing is certain, however, prices will elevate again, and so the urgency remains the same.”

Hodge was among representatives of Guam, Alaska, and Hawaii outlining the challenges remote island electric system operators face in generating electricity. He noted that, like most other islands in the Caribbean, the Virgin Islands has no conventional energy resources to meet its energy needs. “While U.S. mainland utilities can connect to grids to purchase power from other utilities, island utilities are small, isolated, and are not interconnected to a grid comprised of other utilities. This is primarily due to their separation by water and the depth of the ocean floor, which makes interconnection via underwater electric cables technically and economically unfeasible. As a result, island utilities have historically purchased small, simple-cycle generating units that are oil-fueled.”

Hodge told the committee that since fuel prices began to skyrocket more than 10 years ago, WAPA pursued every option to reduce the cost of electric services to the people of the Virgin Islands. “We have pursued alternative and renewable sources tirelessly for almost 10 years now, and tangible relief is finally on the horizon.” WAPA could not, however, have made the advances that it has without a number of strategic public and private partnerships.

He testified that WAPA’s primary supporters have been the executive and legislative branches of the Virgin Islands government, and on the federal level, the Department of the Interior, the Department of Energy’s National Renewable Energy Laboratory, the Federal Emergency Management Agency, and the Department of Agriculture’s Rural Utilities Service. The National Renewable Energy Laboratory helped identify the territory’s baseline energy use and laid out how the Virgin Islands could best meet its goal of achieving a 60% reduction in the use of fossil fuel by 2025. The Interior Department provided a $500,000 grant to prepare an integrated resource plan that provided a roadmap for determining future generation needs. The Federal Emergency Management Agency funded hazard mitigation projects that assisted with burying power lines that serve critical areas of the territory. The Rural Utilities Service approved a loan that allowed WAPA to implement distribution automation technology, including the development of a smart electric grid and advanced metering infrastructure and automated meter reading. Hodge reviewed that, until October 2014, WAPA was 100% dependent on fueloil to produce power. Since that time, the utility has placed on its grid about 8.2 megawatts of solar power.

The Virgin Islands propane conversion project involved more than 200,768 man hours expended on both Saint Thomas and Saint Croix, with about 130,000 hours of local U.S. Virgin Islands man hours, he said. Vitol contracted directly or indirectly with numerous local contractors. Construction took place over 18 months after front-end engineering and design was completed and construction permits were issued.

Storage tanks, manufactured by Geldof Integrated Steel Solutions of Belgium, are mounded, encased by layers of earth, sand, rock, and gravel to maximize safety. Benefits of the installation include providing a significant protective barrier from external damage and fire; elimination of oxygen, preventing uncontrolled ignition; and additional earthquake and hurricane protection. Capacity is 10,400 cubic meters in eight tanks on Saint Croix, which provides 19.2 days of effective supply, while on Saint Thomas there are 14,000 cubic meters in 10 tanks with an 18.3-day supply.

“Facilities were carefully designed to ensure employees’ and the public’s health, safety, and protection,” Hodge emphasized. “There are emergency response plans for each facility and all existing applicable environmental permits and plans are being updated. Fire safety features are designed for 100% redundancy, and firefighting systems are National Fire Protection Association-compliant and include a water blanket to suppress a leak or flame. Facilities are equipped with gas monitoring and leak-detection systems.”

As with any major project, there were challenges. “Throughout the propane conversion process, complications and unforeseen circumstances impacted project progress and the completion schedule — adverse weather conditions, undocumented soil conditions and underground obstacles, and the volume of rock needed to be removed was much greater than anticipated,” said Hodge. He added that there were greater challenges than expected in coordinating the power plant conversions while simultaneously operating the facilities to meet daily electricity demand.

Other circumstances that contributed to project schedule adjustments included extended work that was required for the design, procurement, and installation of the resources to upgrade existing fire protection, controls, and other systems for the safe use of propane, and complexity in permitting, contracting, demolishing, and disposing of structures with lead-based paint. “Then there was the reality of global sourcing of all the materials and equipment for the project,” Hodge elaborated. “And there were additional regulatory requirements to further assure compliance with safety and security of the project’s marine scope, which included new engineering and redesigns.”

WAPA received its first inventory of propane in October 2015 at the Richmond terminal. The fuel was used for commissioning and testing of the storage and delivery systems ahead of the utility’s generating units burning propane to produce electricity. In January of this year WAPA received the long-awaited permit from the U.S. Army Corps of Engineers that allowed it to proceed with work on the marine side of the LPG project at the Randolph Harley Power Plant, and to develop an offshore vessel mooring off Saint Thomas. The permit allowed WAPA to improve, enhance, and convert the existing fuel pier at the Harley plant and the offshore mooring.

All components of the marine work had been dependent on the permit’s approval. WAPA applied for the permit in December 2013. The very large gas carrier (VLGC) permanent mooring site was tied to the permit for Saint Thomas. Prior to its receipt, and so not to delay propane deliveries to Saint Croix, the authority identified a temporary anchoring site for both the feeder-fuel vessels and the VLGC offshore of Aruba.

Other milestones for the project include the completion of mechanical terminal facilities in November 2015, an upgrade of fire suppression systems in January 2016, and the commissioning of propane turbines in February 2016. Major land and water permits for both island projects have been approved, and initial storm water permits for construction activities for both terminals have been issued. An operating storm water permit will be issued after construction is completed. Emergency response plans have been modified and updated to reflect the use of LPG, and a waterway suitability assessment plan, focusing on waterside safety and security, has been approved by the U.S. Coast Guard.

The Virgin Islands Territorial Emergency Management Agency and the U.S. Department of Homeland Security are finalizing an independent vulnerability assessment study to ensure compliance with local and federal mandates for safety and security. “All precautions were taken to protect the wellbeing of the general public, employees, and first responders,” Hodge said. “Partnerships have been structured to expand communication on public awareness, safety, and the security measures of the project.”

Employees are being fully trained on the operation and maintenance of the converted power generation units, including all safety and hazard awareness required for the handling and use of propane. There is also extensive coordination with local fire services and other first responders. Advanced safety and security drills have been conducted with WAPA and local emergency response organizations.

Two new propane delivery vessels, the Epic Curacao and Epic Caledonia, have been built and commissioned to deliver propane to WAPA’s facilities, Hodge said. Crews have conducted advance navigation simulations with Virgin Islands Port Authority harbor pilots to ensure the safe transit of vessels into and out of WAPA docking facilities.

In early April WAPA’s project achieved another milestone when the Unit 20 generating unit on Saint Croix was commissioned for LPG. On Saint Thomas, marine work, including the installation of fenders and other dock improvements to accommodate propane vessels, was proceeding. Work on the land side involved the installation of a marine loading arm. It is anticipated that a similar commissioning of generating units on Saint Thomas would begin in August.

“The LPG project represents the best near-term option for the U.S. Virgin Islands to significantly reduce the cost of fuel for power generation while ensuring widespread benefits for the territory,” Hodge observed. “Propane will provide affordable power and water and lower the cost of living, spur economic growth, enable new business startups, and lower emissions.” —John Needham